Based on Jiangsu Huayu Feiling Packaging Machinery Co., Ltd., Suzhou Langjie Intelligent Industrial Technology Co., Ltd. has fully absorbed the rich, high-quality and professional human resources, technical resources, product resources, market resources accumulated in the beverage, wine, dairy and condiment industries for more than 20 years in the development process of Huayu Feiling packaging machinery Co., Ltd., and has successfully served more than 2000 domestic and foreign customers The practical experience of service should be established. The company is located in China's beverage, wine, dairy, condiment industry science and technology equipment manufacturing center and Huayu Feiling intelligent industrial park, Leyu Town, Zhangjiagang City, which is one of the top three economically developed counties in China.

Suzhou Langjie intelligent is determined to become a modern platform for small and medium-sized aseptic filling and super clean filling equipment and bottle blowing mould technology innovation and intelligent and efficient industrial service platform in the domestic liquid food industry.

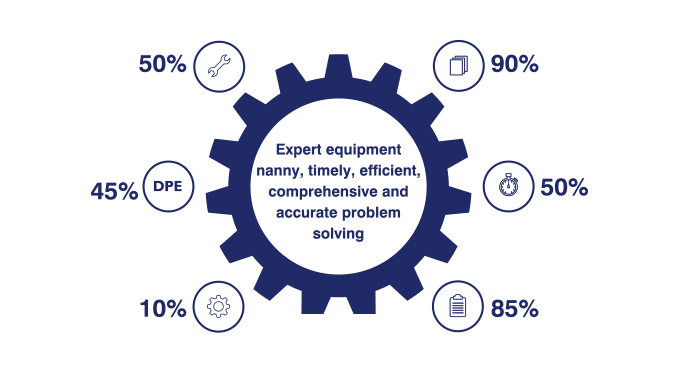

Suzhou Langjie intelligent is committed to promoting the integrated solutions of food and beverage enterprises, including product safety, equipment integrity, continuous and efficient production, energy saving and low consumption, and intelligent control. To bring customers peace of mind, peace of mind, rest assured of advanced production equipment and management and nanny type quality service. We take it our responsibility to provide customers with advanced modern and intelligent production workshops and advanced high-quality equipment, and take professional services and innovation throughout the customer's factory design and construction, production and maintenance of the important concept of "ensuring the safety of production products and reducing the overall production cost", By making full use of advanced and innovative technology and information, we can provide customers with pre project overall consulting service, project equipment evaluation service, project overall process equipment supply service and existing factory performance improvement services, so as to maximize the benefits of food and beverage industry enterprises.